Top Five 3D Dental Lab in China

ASD Dental Lab

ASD Dental Lab is a full service dental laboratory. Our state-of-the-art machines and smart dental technicians let us make a lot of different various dental parts and tools. We can make single dental crowns, bridges, and veneers from things like zirconia. We also make great implants and dentures, like digital dentures.

About Us: Your Partner in Digital Dentistry

ASD is a modern dental laboratory in China with over a decade of experience. When 3D printing technology began to gain traction in the dental industry in 2015, we were already introducing the technology, purchasing related equipment, and obtaining the necessary international certifications.

Dental digital technology not only enables your clinic to obtain more precise information about patients’ oral conditions but also helps us create dental restorations that better fit patients’ teeth. In today’s fully digitalized dental industry, our previous investments have undoubtedly given us a competitive edge. We have developed our own digital workflow system, which can reduce the rework rate of your cases to 1-2%. If you send us digital cases, this rate will be even lower!

3D Printed Crowns and Bridges Cases

At ASD Dental Lab, our advanced 3D technologies allow us to regularly make many different kinds of dental prosthetics and new teeth parts, meeting many different patient needs. Our digital making methods ensure parts are exact, personal, and made fast for all types of products.

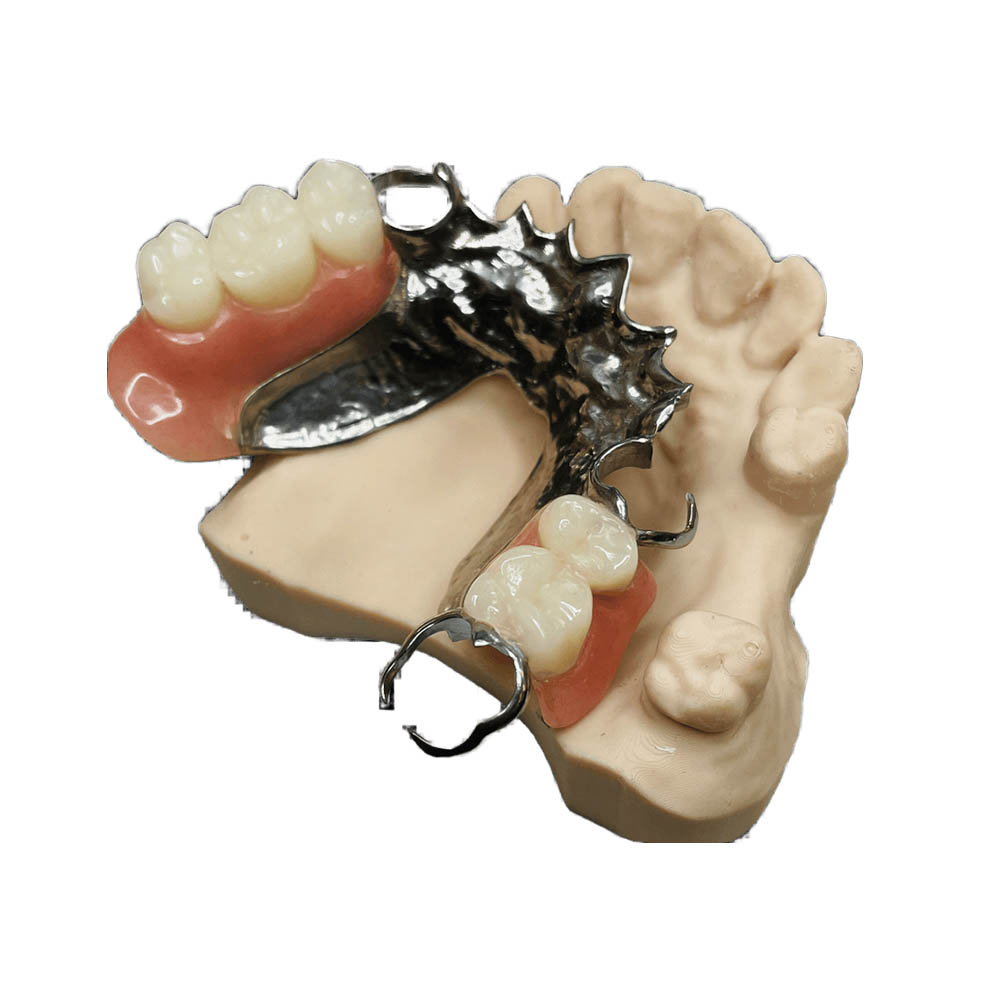

3D Printed Removable Prosthetics Case

Removable prosthetics are designed to be taken out of the mouth by the patient to clean or at night. Our 3D making greatly improves how they fit, feel, and look:

ASD Dental Lab's Quality Check Rules

We check the quality of every 3D-made dental new tooth part against important standards to make sure treatments work well and patients are happy:

Fit at the Edge

Our digital work process, from high-precision scanning to best milling/printing and finishing steps, always makes edge gaps well within what dentists accept (usually less than 50 µm).

How it Looks

We carefully check color matching, see-through quality, surface feel, and natural shape to make sure the new tooth part blends in perfectly with the patient's natural teeth. Best finishing steps, like multi-step polishing and glazing, are key for getting the right shine and stopping stains.

How it Bites

Correct bite contacts and how teeth meet are checked using virtual bite checks in CAD software and final physical checks to make sure the bite is balanced and stops teeth from hitting wrong.

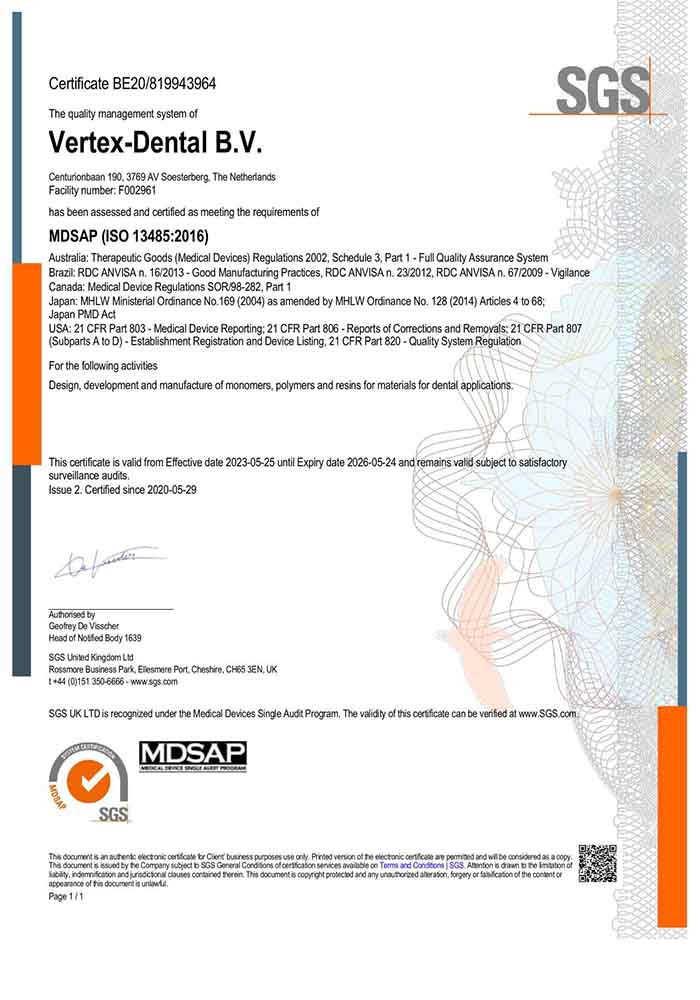

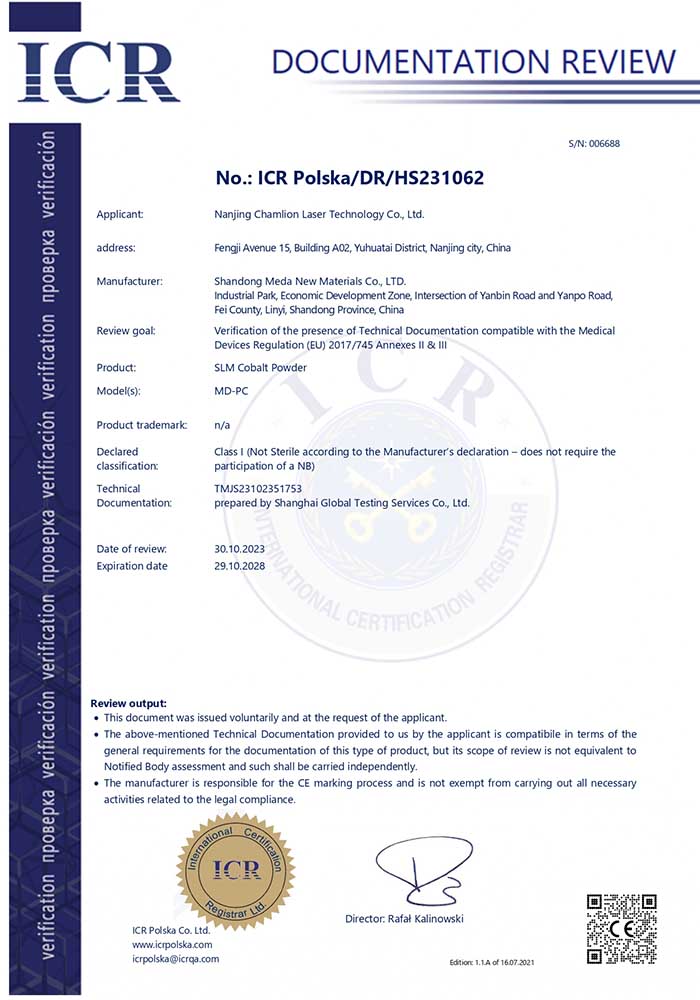

Safe for Body

All materials used are strictly tested and approved to be safe for the body, following international standards (e.g., ISO 10993 series), making sure there are no bad reactions inside the mouth.

Competitive Pricing & Value

As one of China’s top five dental laboratories, our prices give us a competitive edge. Compared to your local dental laboratory, most of our products are more than half the price. This is because we have lower labor costs and streamlined workflows. Send us a trial order and experience ASD’s quality!

Patient-Reported Outcomes and Satisfaction

Our main goal with 3D making is to improve what patients get and how happy they are. For removable partial dentures, for example, what patients say (PROMs) always shows good results:

- Comfort and Fit: Patients say they feel about the same or better, with fewer first-time sore spots and less need for changes after they are put in.

- Aesthetic Satisfaction: More happiness is reported, especially with clear or tooth-colored plastics, because the clips are less seen and they look more natural.

- Getting Used To and Staying In: Getting used to them is usually faster, with fewer visits for changes.

- Digital Workflow Influence: Using in-mouth scanning and digital design leads to happier patients because there’s less discomfort from taking molds and fewer clinic visits.

Send a Cases to ASD 3D Dental Lab

Our way is simple and digital. First, you take a scan with your intraoral scanner. Second, you fill a simple order form on our website. Third, you put the scan file up and send the case. That is it. Your case is now safe in our system, and our team of dental lab technicians can start working on your restoration very fast. This simple way gives you better turnaround times and no worries at all.

ASD Dental Lab's 3D technology

01.

Laboratory Scanners

For harder cases like full sets of teeth, bars supported by implants, or arches with no teeth, lab scanners always get very accurate shapes (usually off by less than 10 μm) and are very repeatable (often off by less than 5 μm when done again). These scanners mostly use special light patterns or blue LED light, which gives more detailed scans and less fuzzy data, especially for shiny or see-through surfaces. They are perfect for scanning old-style molds or physical models with amazing detail. Our lab scanners go through strict regular checks using special items from the maker, often with automatic self-checks, to make sure they are always accurate and can be proven to be so.

03.

CAD & CAM Software

After the digital scan is taken, the information is put into advanced CAD software, which is key to how we design things. Our expert digital designers use these strong tools to:

1. Design New Teeth Parts: Make exact 3D models of crowns, bridges, veneers, dentures, and other tooth parts, making sure they have the best fit, how they work, and how they look.

2. Virtual Bite Check: Copy how top and bottom teeth meet and move to make sure the bite is correct and works well.

3. Make it Personal: Change designs to fit each patient's body and medical needs, including edges, where they come out of the gums, and natural curves.

Once the design is approved, the digital model is sent to CAM software. This software changes the design into instructions machines can understand to make the part. This includes making the cutting paths best for milling machines or getting print files ready for 3D printers, making sure materials are used well and parts are made exactly right.

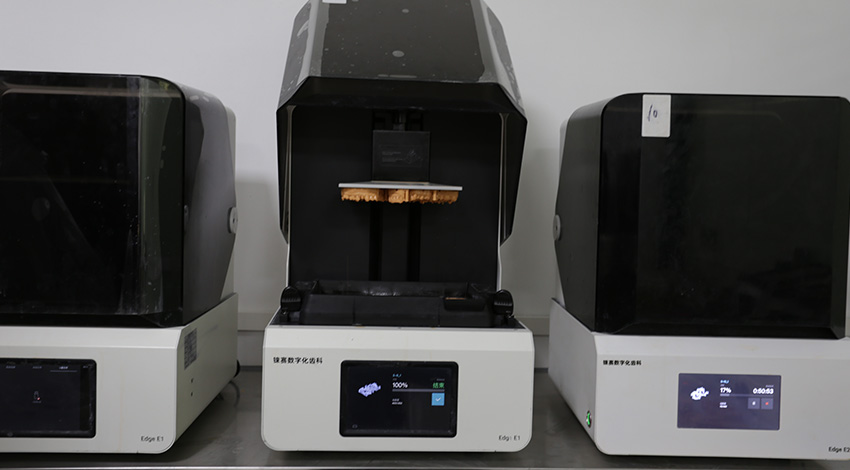

02.

3D Printing Methods

3D printing is a main part of what we can make, letting us produce many different dental devices faster and more accurately than ever before. We use various 3D printing technologies, each good for certain materials and uses:

1. Stereolithography (SLA): Known for making very detailed and smooth parts, SLA is great for printing very detailed models, guides for surgery, and some temporary tooth parts.

2. Digital Light Processing (DLP): Prints faster than SLA, especially for bigger groups. DLP is great for models, molds for aligners, and some parts that support prosthetics.

3. Material Jetting (PolyJet/MultiJet Printing): This method lets us print with many materials, making it possible to create models with different material qualities (e.g., hard and bendy parts) or even multi-color tooth parts, meaning less hand coloring is needed.

4. Selective Laser Sintering (SLS) and Direct Metal Laser Sintering (DMLS): These methods are used for making metal frames, such as cobalt-chromium (CoCr) or titanium, giving them very strong and safe for the body for complicated tooth parts and implant pieces.

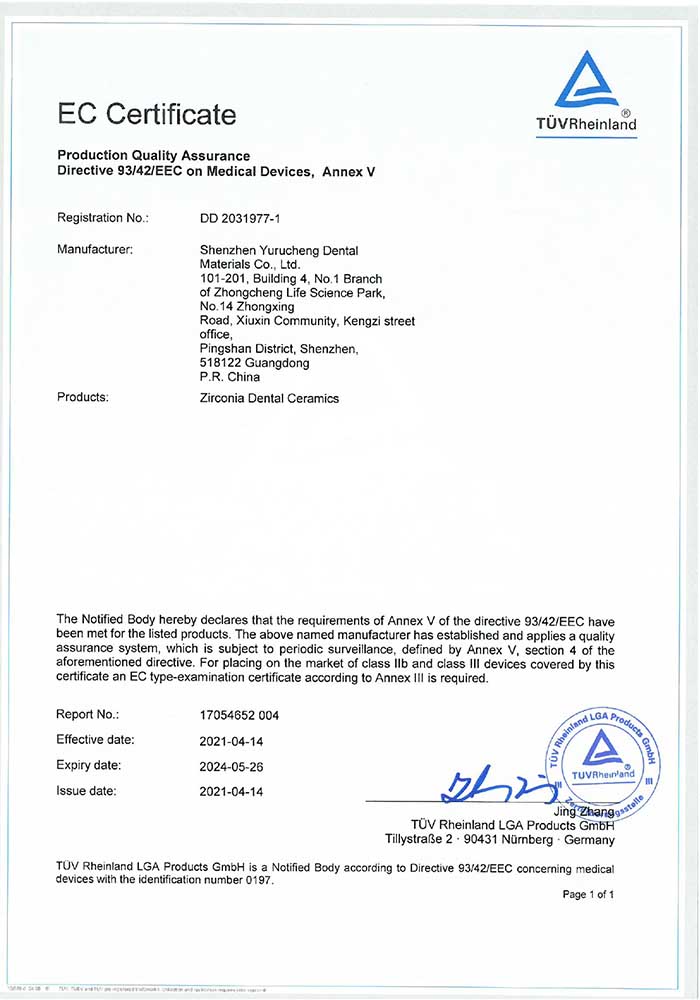

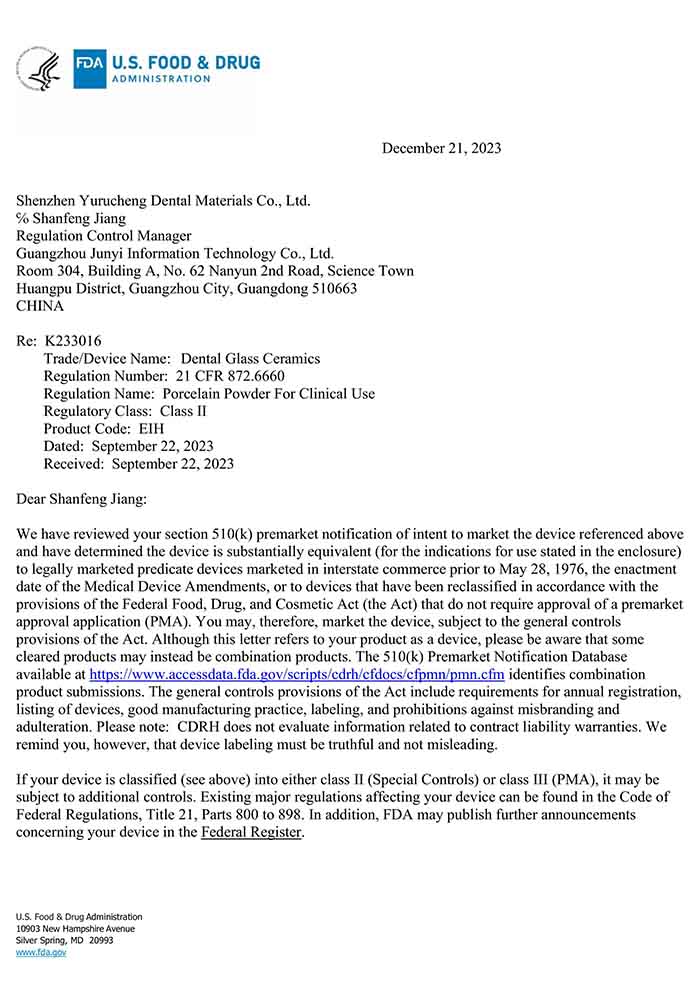

Certificates ASD Have Obtained

We’re a top-3 3D dental lab in China, CE & FDA & ISO certified, NADL member. 25 years of quality restorations, implants, and dentures. Your trusted dentistry partner.

What Our Doctor’s Say

"ASD 3D Dental Lab has completely transformed my practice. The precision of their 3D printed parts is incredible, and my patients love the natural look and feel of their new smiles."

"The workflow with ASD is seamless. I can easily send digital impressions, and the restorations I receive are always a perfect fit. Their dental 3d solutions have save me a lot of trouble."

I've worked with many dental laboratories, but ASD stands out for their exceptional customer service and commitment to quality. Their dental crowns are top-notch, and they use top material.

"The turnaround time is amazing! ASD 3D printing dental lab helps me keep my schedule on track, and my patients appreciate the quick service of receiving their denture."

"I highly recommend ASD Dental Lab to any dentist looking for a reliable partner. They are providing high-quality product with competitive pricing."

Experience faster turnaround times with our cutting-edge technology

Frequently Asked Questions

We take STL files from all big dental scanners and dental software systems. This is what everyone uses and makes sure the file moves smooth from your clinic to our 3d dental lab.

Because of our fast digital workflow, our turnaround is much quicker than old labs. A single zirconia crown can often be designed, made with a mill, and shipped in just a few work days. We will give you a time when you send your case.

Yes. A full digital way is best, but we are a cutting-edge digital lab that can also work with good old PVS molds. We can scan them here in our lab to bring your case into our digital workflow. We can help you change to digital when you are ready.

Latest from Blog

Explore dentistry trends, dental lab insights, digital dentistry updates, and tips for dentists on implants, crowns, restorations, and dental technology.

Do Dentists Take Medicare? Understanding Your Dental Coverage Options in 2025

That feeling of confusion when you try to book a dental cleaning and the receptionist asks, “What insurance do…

Do Dentists Take Medicaid? My Guide to Navigating Dental Coverage

Understanding Medicaid Dental Coverage: My Personal Journey If you’re like me, dental insurance feels like a jigsaw puzzle. When…

Do Dentists Pull Teeth? Your Clear Guide to Tooth Extractions

That nagging toothache that keeps you up at night. The sudden jolt when you bite into something cold. Or…