A Complete Guide to Dental Waxes: What They Are, What They Do, and How They’re Used

Ever wonder how dentists make a crown or denture that fits your mouth perfectly? It seems like magic. But that “magic” often starts with something surprisingly simple: dental wax. This guide will pull back the curtain on the amazing world of dental waxes. You’ll learn about the different dental wax types, what they do, and why they’re a huge part of your smile. It helps you appreciate why top-notch dental work requires both skill and the right stuff.

Table of Contents

What Are Dental Waxes, and Why Should You Care?

You’ve seen wax in candles and crayons. Dental waxes are similar but they’re way more specialized. They’re a blend of natural waxes like beeswax or carnauba wax and synthetic materials. Think of a dental technician as a sculptor. In their hands dental wax becomes a special kind of clay. They use it to craft a perfect model or pattern of a tooth, crown, or denture before making the real thing from a tougher material.

The big problem happens when a dental piece like a crown or a dental bridge just doesn’t fit. It might feel bulky cause pain when you chew or simply look off. That’s a real headache. It means more appointments and more hassle for you. Often these issues trace back to a tiny slip-up with the wax model. If the wax pattern is wrong by even a hair’s width the final crown will be wrong too. This frustrating problem is called wax distortion dental casting.

The solution is to use the right wax and to handle it with care. That’s why understanding dental wax properties is a basic part of restorative dentistry and prosthodontics. When your dental team knows the ins and outs of these waxes they lay the groundwork for a flawless fit. This guide gives you that inside scoop explaining everything from inlay wax composition to the lost wax technique dental pros use every day.

How Are Dental Waxes Sorted?

Not all waxes are created equal. A dentist can’t just grab a candle to make a model for your new tooth! Dental waxes are sorted into three main groups based on their job. This dental wax comparison helps the dental laboratory choose the right tool for the task at hand.

The three groups are:

- Pattern Waxes: These create the exact shape of your future tooth or filling.

- Processing Waxes: These are helper waxes used during the lab work.

- Impression Waxes: These take a copy or “impression” of your teeth and gums.

Each group contains different waxes with their own special features or ideal wax characteristics. For instance some need to be hard to hold their shape while others must be soft and easy to bend. Let’s dive into what makes each group unique. Groups like the ADA (American Dental Association) and ISO Standards help make sure these waxes are safe and work like they’re supposed to.

What is Pattern Wax and How Does It Shape Your Smile?

Pattern waxes are the true artists of the dental lab. A dental technician uses them to build a model of what your final tooth, crown, or denture part will look like. This model called a wax pattern has to be perfect. Any little mistake in wax patterns for crowns will be copied right into the final piece. That’s why getting the casting pattern accuracy just right is a huge deal.

There are three main kinds of pattern wax dentistry relies on:

- Inlay Wax: Technicians use this for small jobs like inlays and onlays, which are like custom-made fillings. You can carve it into tiny, detailed shapes without it chipping or flaking. It has a very low flow of dental waxes at body temperature which just means it won’t get soft and lose its shape inside your mouth.

- Casting Wax: This wax helps make patterns for bigger items like the metal skeleton for partial dentures or a whole crown (dentistry). It comes in sheets or ready-made shapes. Its most important feature is that it burns away clean leaving nothing behind. This process is called wax burnout and it leaves no dental wax residue. This is crucial for the lost wax technique where the wax model is swapped out for metal.

- Baseplate Wax: This pink wax is probably the one you’d recognize. Common baseplate wax uses include making the foundation for a denture try-in. You’ve seen it if you’ve watched someone get fitted for complete dentures. It’s solid enough at room temperature to hold fake teeth in position so you can see how they’ll look and feel before they’re finished. It’s also used to build occlusal wax rims to check how your teeth bite together.

What Do Processing Waxes Do Behind the Scenes?

If pattern waxes are the stars of the show then processing waxes are the talented stagehands working backstage. They don’t end up in your mouth but they help make the whole process of creating your dental work happen. They’re the unsung heroes of the dental lab and are sometimes called lab procedure waxes.

Here are a few of the key players:

- Boxing Wax: Picture a Jell-O mold. Boxing wax works like the wall of that mold. After your dentist takes an impression of your teeth a technician wraps a strip of it around the impression to form a container. Then they pour a stone material inside to make a perfect dental model (cast). The boxing wax technique is simple but very important.

- Utility Wax: Think of this as the duct tape of the dental world. The uses for utility wax in a dental lab are endless. It’s soft sticky and bendy. A technician might use it to customize an impression tray so it fits your mouth more comfortably or for border molding.

- Sticky Wax: Just like the name says this stuff is super sticky when it’s melted but it becomes hard and brittle once it cools down. Common sticky wax applications include holding broken denture pieces together for a repair or tacking metal parts together before they’re permanently joined.

- Blockout Wax: When a model is made from your teeth it might have little dips and crevices called undercuts. For something like a partial denture to fit properly these spots need to be filled. Technicians use blockout wax to fill these undercuts so the final piece slides on and off without a hitch.

How Do Impression Waxes Capture Every Little Detail?

The third group is impression waxes. Their main job is to get a super-accurate copy of parts of your mouth. They need to be soft enough to flow into every tiny groove but become firm enough to hold that shape when they’re removed. This is the secret to a great fit.

Here are two main types of impression wax for dentures and other dental work:

- Bite Registration Wax: Getting your bite right is one of the most critical steps. If your top and bottom teeth don’t line up correctly it can lead to all kinds of trouble. Your dentist uses bite registration wax to record exactly how your teeth meet. You bite down on a soft wafer of this wax and it hardens capturing your unique bite. This record helps set up your models on a special machine called an articulator.

- Corrective Impression Wax: Sometimes a dentist needs an extremely exact impression of your soft gums especially for dentures. They paint corrective impression wax onto an existing impression and place it back in your mouth. Your body heat makes the wax flow gently capturing the details of your gums without pressing on them. It’s perfect when making comfortable dental prostheses where comfort is everything.

And let’s not forget orthodontic wax. If you’ve ever had braces you know this one! It’s a soft clear wax you press over a sharp bracket to keep it from poking your cheek. Its only job is to keep you comfortable.

What Are the “Superpowers” of Dental Waxes?

What makes one wax hard and another soft? Why does one burn away cleanly while another gets sticky? It all comes down to their properties or features. Understanding these helps a dental student or technician master their work. Think of them as the wax’s superpowers.

Here are the most important features you’d find on a dental wax properties chart:

- Thermal Properties: This is all about how wax handles heat.

- Melting Range: Waxes don’t just melt at one specific temperature like ice. Instead they soften over a melting range. This lets technicians carve and shape them. The dental wax melting point is a key feature.

- Thermal Expansion and Contraction: When you heat wax it gets bigger. When it cools it shrinks. This property called thermal expansion is super important because too much shrinking (dental wax contraction) can mess up the fit of a crown. This is a big topic in dental materials science wax studies.

- Flow: This measures how much the wax moves or “flows” under pressure at a specific temperature. A wax needs to flow enough to catch all the details but not so much that it droops and loses its shape. The study of how materials flow is part of dental wax rheology.

- Mechanical Properties: This is about how the wax deals with force.

- Hardness and Rigidity: A pattern wax has to be hard so it can be carved without breaking. Rigidity is what helps it resist bending.

- Ductility and Malleability: This means a wax can be bent or shaped without breaking. A wax like utility wax needs to have high dental wax ductility and dental wax malleability.

- Strength and Brittleness: Some waxes like sticky wax are strong when they’re cool but they’re also brittle. This means they’ll snap before they bend.

All these properties come from the wax’s ingredients which is a major topic for waxes in dental education. They are made from natural stuff like paraffin wax in dentistry beeswax candelilla wax or microcrystalline wax dental grade. They also contain synthetic waxes and other additives like resins and oils. These special ingredients in resin modified waxes give them their unique powers.

Where Do You See Dental Waxes in Action?

You can find dental waxes being used in just about every part of dentistry. They are key tools for work done in the dentist’s office (dental wax clinical applications) and in the lab (dental wax laboratory applications).

Let’s look at a few examples:

- Fixed Prosthodontics: This is the world of crowns and bridges. When making a wax for crown fabrication or a wax for bridge fabrication a technician does a “waxing up.” They build the tooth shape on the model creating a design that is both beautiful and works well. This often starts with a diagnostic wax-up to plan out the whole case.

- Removable Prosthodontics: This is all about dentures. We already mentioned using baseplate wax to set up teeth for a try-in. Technicians use casting wax to create the metal framework for partial dentures.

- Orthodontics: Besides the comfort wax for patients labs use special wax for orthodontics to help make some appliances.

- Dental Impressions: We saw how utility wax can help customize an impression tray and how bite registration wax records your bite. These are key uses for dental wax for dental impressions.

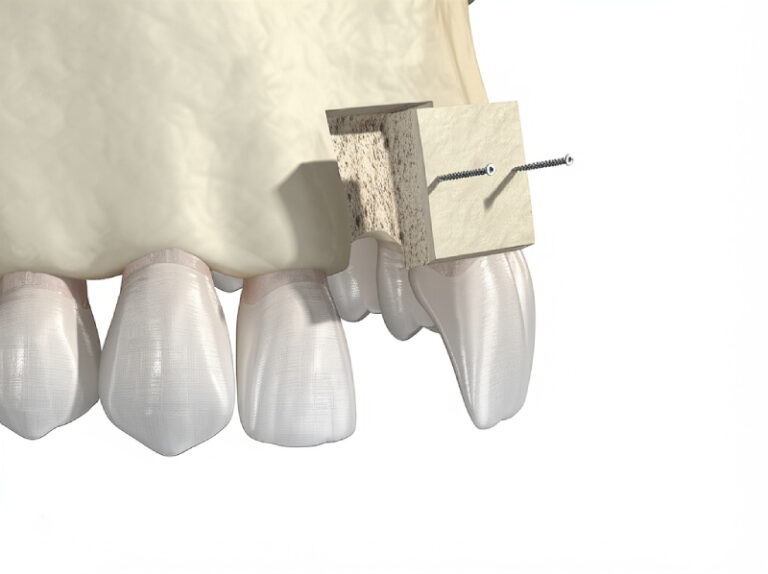

The whole process often relies on the lost wax technique. This ancient method is still one of the best ways to make exact metal parts. The technician makes the wax pattern attaches wax rods called sprues and then covers everything in a plaster-like material called investment material. When this is heated in a burnout furnace the wax melts and runs out leaving a hollow mold behind. Melted metal (casting alloy) is then shot into this space creating a perfect metal copy of the wax pattern. This whole process is called investing dental wax patterns.

How Can You Avoid Common Wax Mistakes?

Working with wax takes real skill. A tiny mistake can snowball into a big problem. The number one enemy is wax distortion. This happens when the wax pattern bends or warps leading to a poorly fitting crown or denture.

Here are some tips from the pros for troubleshooting wax patterns:

- Heat It Evenly: When you melt wax go slow and steady. Using a controlled wax pot (heater) is much better than an open flame from a Bunsen burner. Overheating can make the wax brittle.

- Add in Small Bits: When building up a wax pattern add the wax in little layers. This cuts down on residual stress which is tension trapped inside the wax that can make it warp later on.

- Carve with Care: Use sharp wax carving instruments like a wax knife dental tool. Dull tools will just drag and bend the wax.

- Invest Quickly: Once a wax pattern is done don’t let it sit on the counter. The longer it sits the more likely it is to warp. It should be invested in the stone material right away to lock in its shape.

- Store It Right: Storing dental waxes properly is also important. Keep them in a cool dark place and away from sunlight. Heat can soften them and make them lose their shape.

By following these dental wax manipulation tips technicians can prevent the most common defects in wax work. This helps make sure the final piece fits great which saves you time and trouble.

How Do You Pick the Right Wax for the Job?

With so many choices how does a dental pro pick the right one? They think about a few key things:

- What’s the job? Are they making a tiny inlay or a large denture base? The task itself points to the right type of wax. You wouldn’t use soft utility wax to carve a detailed crown.

- What features are needed? Does the wax need to be hard? Does it need to flow easily? Does it need to burn off completely? The properties of dental waxes have to match what the job needs.

- What method will be used? Is it being done directly in the mouth or in the lab? This changes the wax choice.

- Read the Instructions: Different dental wax brands can have slightly different instructions. Following them is key to getting it right. They also provide a dental wax safety data sheet.

The table below is like a cheat sheet for choosing dental waxes.

Data Table: Key Features of Common Dental Waxes

| Feature/Metric | Inlay Wax (Type I – Hard) | Casting Wax | Baseplate Wax (Type I – Soft) | Bite Registration Wax | Utility Wax |

|---|---|---|---|---|---|

| Common Use | Inlays, Crowns | Denture Frameworks, Bridges | Denture Try-in, Occlusal Rims | Recording Your Bite | Modifying Trays |

| Softening Range (°C) | 55-65°C | 50-70°C | 45-55°C | 40-50°C | 35-45°C |

| Flow at Mouth Temp (37°C) | Very Low (<1%) | Very Low (<0.5%) | High (>85%) | Very High (>95%) | Very High (>98%) |

| Ash left after Burnout | Very Low (<0.1%) | Extremely Low (<0.05%) | Low (<0.2%) | Low (<0.2%) | Higher (<0.5%) |

| Hardness | High | Medium-High | Low | Very Low | Very Low |

| Problem it Solves | Prevents tiny leaks in fillings | Makes sure metal castings are accurate | Stops dentures from warping | Makes sure your bite is right | Helps fit trays to your mouth |

As you can see the job drives the choice. An expert in dental technology wax knows this chart by heart.

What’s Next for Dental Waxes?

You might think wax is old-school. While the history of dental waxes goes way back they are still incredibly important today. Modern dental waxes are better than ever with more exact features.

The biggest change is the growth of digital dentistry. Many crowns are now designed right on a computer (CAD/CAM). But this doesn’t mean wax is obsolete! Technicians often still use a diagnostic wax-up to plan a tricky case before they scan it into the computer. There’s even digital wax-up software now.

In the future we’ll see even more specialized dental waxes and new materials that mix the simple handling of wax with the accuracy of digital tools. For now though mastering traditional dental waxing techniques is still a key skill. It’s the art and science behind a perfect smile.

To wrap it all up dental waxes aren’t just lumps of wax. They are highly advanced materials that are essential for creating dental work that fits well feels comfortable and looks great.

Key Things to Remember:

- Dental waxes are special materials used to make models for crowns dentures and other dental pieces.

- They are sorted into three main types: pattern, processing, and impression waxes.

- Features like melting range flow and hardness decide what a wax is used for.

- Handling wax correctly is the key to avoiding warping and making sure the final piece fits perfectly.

- The lost wax technique is a classic method used to turn a wax model into a metal part.

- Even with today’s digital technology understanding wax is still a key part of modern restorative dentistry.