FDM vs. SLA 3D Printing: What You Need to Know

Do you want to print 3D things? You need to know about FDM and SLA. They are two big ways to make 3D stuff. Let me help you pick the best one!

Table of Contents

What Are FDM and SLA?

FDM means Fused Deposition Modeling. It uses hot plastic that comes out of a tube.

SLA means Stereolithography. It uses light to make hard resin.

They are very different! Let’s see how they work.

How They Work

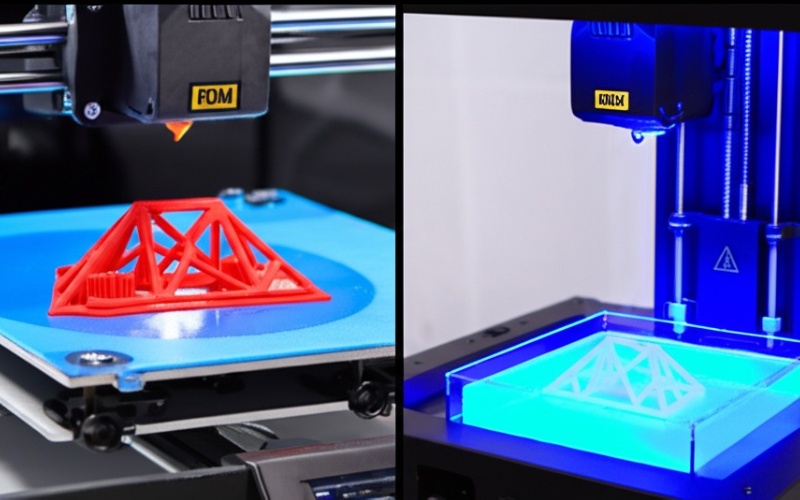

FDM: Plastic String Magic

- Has a hot end that melts plastic

- Moves around and puts down layers

- Like a hot glue gun that makes shapes

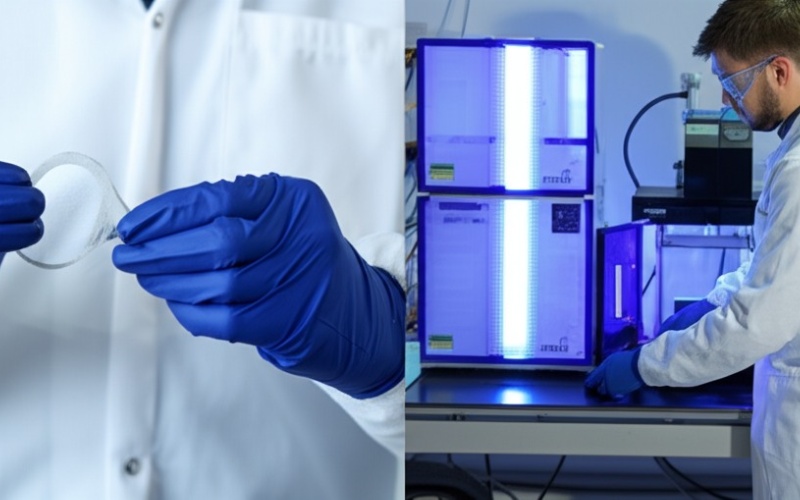

SLA: Light-Hardening Goo

- Has a vat full of liquid resin

- Uses UV light to make it hard

- Makes things upside down in a tank

Big Differences Between FDM and SLA

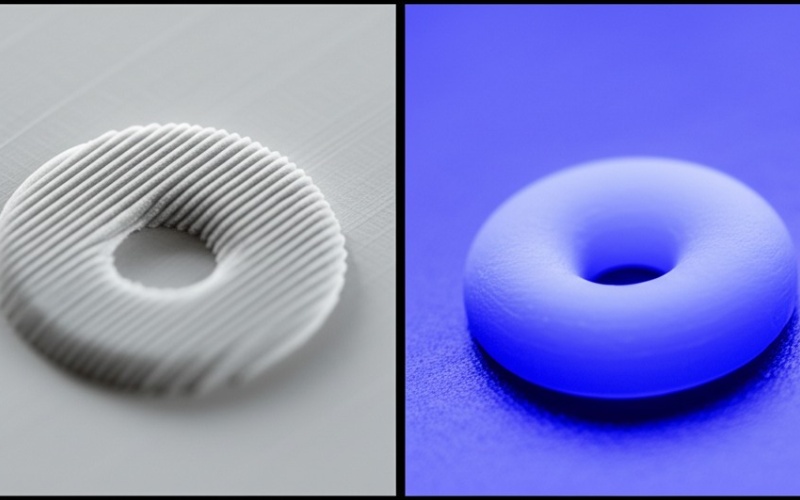

How Things Look

FDM stuff has lines you can see. SLA stuff is smooth like glass!

| FDM | SLA |

|---|---|

| You can see the layers | Very smooth surface |

| Looks a bit rough | Looks nice and clean |

| Not good for small details | Great for tiny details |

FDM is like building with Legos. SLA is like carving from smooth clay.

What You Can Make Them From

FDM uses:

- PLA (plant plastic)

- ABS (toy plastic)

- PETG (bottle plastic)

- Nylon (strong plastic)

- TPU (bendy plastic)

SLA uses:

- Tough resin

- Flexible resin

- Dental resin

- Biocompatible resin

- Clear resin

FDM has more types of materials you can use!

How Strong Things Are

FDM parts are anisotropic. That means they break easier between the layers.

SLA parts are isotropic. That means they are the same strength all over. But they can be more brittle like glass.

What You Do After Printing

With FDM, you just:

- Take off supports

- Maybe sand if you want

With SLA, you MUST:

- Wash in IPA alcohol

- Cure with UV light more

- Cut off supports

- It’s messy and needs gloves!

How Much It Costs

FDM is your friend if you don’t have much money:

- Cheap printers ($200-$5,000)

- Cheap plastic ($20-$80 per kg)

SLA costs more:

- Expensive printers ($3,000-$100,000)

- Expensive resin ($80-$400 per liter)

How Fast It Prints

FDM is faster for big things.

SLA is slower because the resin needs time to harden.

What Each One Is Best For

Pick FDM When You Need:

- Cheap parts

- Strong parts that won’t break

- Big things

- Simple shapes

- Don’t care about pretty details

FDM is perfect for fixtures and jigs that need to be strong but don’t need to look perfect.

Pick SLA When You Need:

- Pretty things with tiny details

- Smooth surfaces

- Small parts that look nice

- Dental models

- Jewelry models

SLA works great for making master patterns for precision metal machining when you need perfect details.

Real World Examples

FDM Success Story

A drone company used FDM with carbon fiber plastic. This made parts 90% faster than before. The parts were strong enough to fly!

SLA Success Story

A dentist used SLA to make teeth models. They were so precise (within 0.1mm) that they fit perfectly in people’s mouths. It saved the dentist 40% money!

FDM and SLA by the Numbers

| What We Compare | FDM | SLA |

|---|---|---|

| How Precise | ±0.5 mm | ±0.1 mm |

| Surface Smoothness | Rough (like sandpaper) | Smooth (like glass) |

| Printer Cost | $200-$5,000 | $3,000-$100,000 |

| Material Cost | $20-$80 per kg | $80-$400 per liter |

| Print Speed | Faster for big things | Slower (needs curing) |

| Layer Lines | Very visible | Almost invisible |

| Best Uses | Tools, big parts | Jewelry, small detailed parts |

The Good and Bad

FDM Good Points:

- Cheap to buy and run

- Easy to use

- Many materials

- Not much mess

- Big print size

FDM Bad Points:

- Rough looking

- Weak between layers

- Not good for small details

- Visible lines

SLA Good Points:

- Beautiful smooth finish

- Tiny details possible

- Same strength all over

- Professional looking parts

SLA Bad Points:

- Messy resin

- Smelly chemicals

- More steps after printing

- Brittle parts that can snap

- More expensive

Which One Should You Pick?

If you are new to 3D printing:

- Start with FDM – it’s easier and cheaper

If you are a professional:

- Use SLA for models that customers will see

- Use FDM for tools and test parts

If you make jewelry or dental things:

- SLA is your only good choice!

For making parts that will work with CNC machining processes later, both can work well. FDM is good for making simple jigs, while SLA makes better visualization models.

Questions People Ask

Is SLA stronger than FDM?

No, not always! It depends on what you need. SLA is the same strength all over, but can be more brittle. FDM can be stronger for parts that need to bend without breaking if you pick the right plastic.

Can SLA printers use FDM materials?

No! They are completely different. FDM uses solid plastic strings. SLA uses liquid resin that hardens with light.

Is resin printing toxic?

Yes, SLA resin can be bad for you! You need good air flow and must wear gloves. The smell is not good for you to breathe.

Which is better for making prototypes?

For fast, cheap prototypes that just need to work, use FDM. For prototypes that need to look pretty for people to see, use SLA.

Special Uses

For Making Things That Move

If you need parts that move like hinges, FDM is often better because the parts don’t stick together as much after printing.

When you need to make patterns for cnc metal spinning, SLA gives you the smooth surface finish required.

For School Projects

FDM is better for schools:

- Safer for kids

- Cheaper when it breaks

- Faster to make things

Final Thoughts

Both FDM and SLA are good, just for different things!

If you need more help picking the right technology for your project, especially one that might later need cnc metal parts, feel free to ask more questions!

Remember:

- FDM = cheap, strong, rough

- SLA = pretty, detailed, more work

Now you know the big differences between FDM and SLA 3D printing! Which one will you pick for your next project?